In the demanding world of precision machining and jig and fixture manufacturing, the reliability of your tooling components is paramount. Our Hardened Steel Plain Drill Bush delivers exceptional durability and accuracy, engineered to withstand high-volume production cycles and resist wear from abrasive materials. For applications requiring the absolute pinnacle of dimensional stability and surface finish, we offer specialized solutions such as our DIN179A Precision Drill Bushings, which adhere to stringent international standards. When extreme hardness and wear resistance are non-negotiable, particularly for high-speed or exotic material applications, our Cemented Carbide Precision Bushing Sleeves provide an unparalleled solution, significantly extending service life and maintaining tighter tolerances over time.

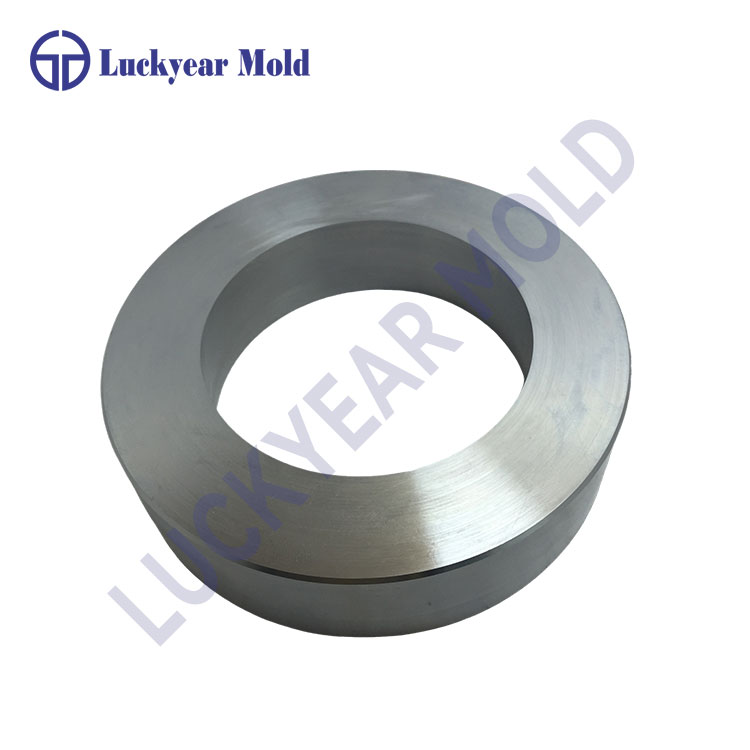

The Hardened Steel Plain Drill Bush is the cornerstone of reliable drill guidance. Manufactured from high-grade steel and through-hardened to a precise Rockwell hardness, this bush is designed to provide a long-lasting, stable bore for cutting tools. Its plain, unflanged design offers versatility for press-fitting into various jig plates and fixtures, ensuring a secure and accurate installation. The internal diameter is honed to a fine finish, minimizing friction and tool wear while maximizing the accuracy of the drilled hole. This fundamental component is essential for maintaining consistent part quality and protecting expensive drill bits from deflection and breakage.

Hardened Steel Plain Drill Bush Key Specifications

Our Hardened Steel Plain Drill Bush is available in a comprehensive range of standard sizes to meet diverse industrial needs. The table below outlines the core dimensional specifications.

| Nominal Bore (mm) | Outside Diameter (mm) | Overall Length (mm) | Hardness (HRC) | Standard Tolerance |

|---|---|---|---|---|

| 3.0 | 8.0 | 15.0 | 60-64 | H6 |

| 5.0 | 10.0 | 18.0 | 60-64 | H6 |

| 8.0 | 15.0 | 22.0 | 60-64 | H6 |

| 10.0 | 18.0 | 25.0 | 60-64 | H6 |

| 12.0 | 20.0 | 28.0 | 60-64 | H6 |

Product Features & Benefits

- High Wear Resistance: Through-hardening ensures extended service life under continuous use, reducing downtime for replacements.

- Precision Ground Bore: The internal diameter is precision honed for a superior surface finish, promoting smooth tool operation and accurate hole location.

- Dimensional Stability: Manufactured to tight tolerances, ensuring consistent performance and reliable fit in jig plates.

- Versatile Application: Suitable for a wide range of drilling operations in metalworking, woodworking, and composite material fabrication.

- Cost-Effective: Provides an optimal balance of performance and value for standard drilling applications, protecting more expensive cutting tools.

- Material Integrity: Made from high-quality alloy steel, heat-treated for optimal core toughness and surface hardness.

Typical Applications

- Drilling jigs and fixtures for mass production

- CNC machine tool accessories

- Template guidance for manual drilling operations

- Assembly line tooling for automotive and aerospace components

- Repair and maintenance of existing jigs and fixtures